Infrastructure

OUR INFRASTRUCTURE

Manufacturing with quality

Fully equipped manufacturing facility with the latest machines and technologies.

We have established the manufacturing facility with state-of-the-art machinery intending to manufacture the best quality of Fabrics and Sacks ith minimum quality variations. Our well-built and richly equipped factory occupies 1,50,000 Sq.ft. and has the latest machines and technologies with 1200 MT per month installed to process woven polypropylene fabrics on circular looms.

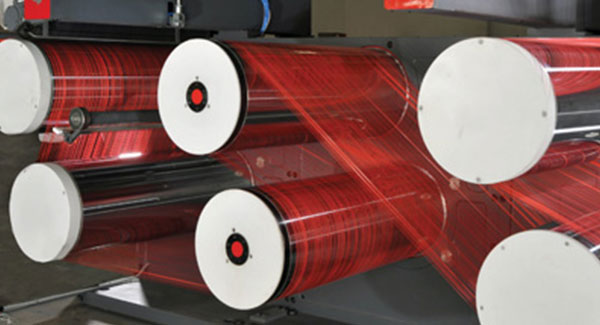

Tape Plant

Here the tape required to make PP woven bags is produced. We have a quality-driven process for mixing and melting virgin PP granules and for conversion into the form of tapes in an extrusion plant. At the end of the process, the tapes are wound on bobbins of the required size. This is the first stage of the process that determines the tape's tensile strength. We house four tape plants with a total of 270 looms (Lohia & JAIKO) and a whopping capacity of 1200 MT/month.

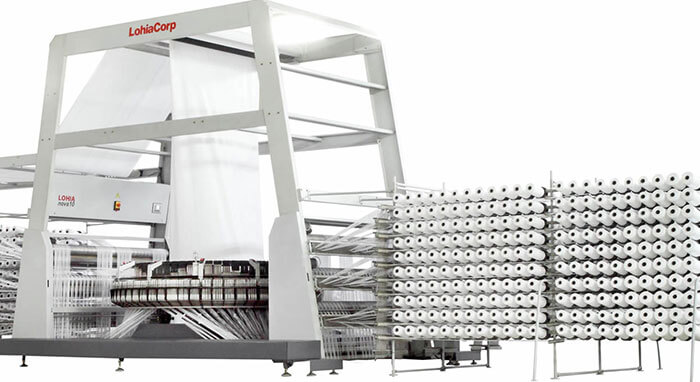

Looms

Here the PP woven Fabric to produce PP woven bags is made using tapes

producer in the tape plant, or extruded tape bobbins will be loaded in the circular weaving machine. The tapes are then woven into the fabric of the required specification and will be

in roll form. These fabrics will become the body fabric of the PP woven bag.

Modi Propac has precision quality looms that can simultaneously weave up to 2,000 bobbins.

Lamination

Lamination of woven bags is a process in which coating of required

thickness(measured in GSM) is done using polymers material. Lamination is done on PP woven fabric to prevent moisture and dust from entering the bag. We use state-of-the-art technology

to laminate PP and LDPE bags and house three extrusion & coating plants with a combined capacity of 700MT/month.

We perform strict quality checks to ensure complete moisture control and dust control. Our laminated bags are used in FDA, ISI and BIS-approved foodgrain, processed food industries

Printing

Here PP bags are printed with the matter provided by customers. Our machines are capable of the roll to roll, individual bag printing, and printing up to seven colors on a bag. Our finishing unit can process 100k bags daily.

Liner

Liner bags are mainly used to provide added moisture and dust protection. Liner for bags are mostly inserted into a PP woven bag and stitched (sewn)from the top and/or bottom. Modi Propac employs highly efficient machinery for mass lining and production of Liner bags.

Gussetting

It's a process in which the vertical sides of PP woven bags are folded inwards. We have customers using this in large quantities because it gives them stability while stacking their bags. We also produce a transparent gusset so that customers can view the quality of material through it.